Complete inventory control from supplier to customer. Track every ingredient, manage recipes, and get instant traceability when you need it most—all in one powerful platform.

Can't quickly answer "where did this ingredient go?"

No visibility into what's about to expire

Hours wasted on manual stock counts and reconciliation

Traceability reports take days to compile for audits

No way to track Work In Progress batches

Lost certificates and expired supplier documentation

When an auditor asks “Show me everywhere this supplier’s flour went,” do you panic? Most food manufacturers spend days manually searching through paperwork and spreadsheets to answer simple traceability questions.

Running out of critical ingredients stops production. Over-ordering ties up cash in excess inventory. Manual stock counts waste hours and are prone to errors.

Recipe changes aren’t documented. Substitute ingredients used without tracking. No way to know which recipe version was used in historical batches.

A supplier notifies you of a potential contamination in ingredient batch #12345. With QTRACA, you identify all affected products in 2 minutes, contact the 3 customers who received them within 5 minutes, and have a complete traceability report ready for authorities in 10 minutes.

An auditor asks: "Show me everywhere wheat flour from ABC Supplier went in March." Instead of spending 2 days searching paperwork, you pull up the report in 30 seconds, showing every WIP batch, finished product, and customer who received it.

Your primary cocoa powder is out of stock. Your team uses the approved substitute, QTRACA tracks it automatically, and you can prove which batches used the substitute for allergen declarations and costing.

Food traceability software tracks ingredients and products throughout your supply chain—from supplier receipt through production to customer dispatch. It creates a digital chain of custody showing where every ingredient came from, which batches used it, what finished products were created, and which customers received them. This enables rapid response during recalls and proves due diligence during audits.

Upstream traceability (backward tracing) means tracking ingredients back to their source—identifying which supplier provided an ingredient and which batches it was used in. Downstream traceability (forward tracing) means tracking products forward to customers—identifying which customers received products containing a specific ingredient. QTRACA provides both directions instantly with one-click traceability reports.

Instantly. When you need to trace an ingredient or batch, simply click on it in QTRACA and you’ll immediately see everywhere it came from and everywhere it went. Generate comprehensive PDF or Excel reports in seconds showing the complete chain of custody. During recalls or audits, what used to take days of manual searching now takes 30 seconds.

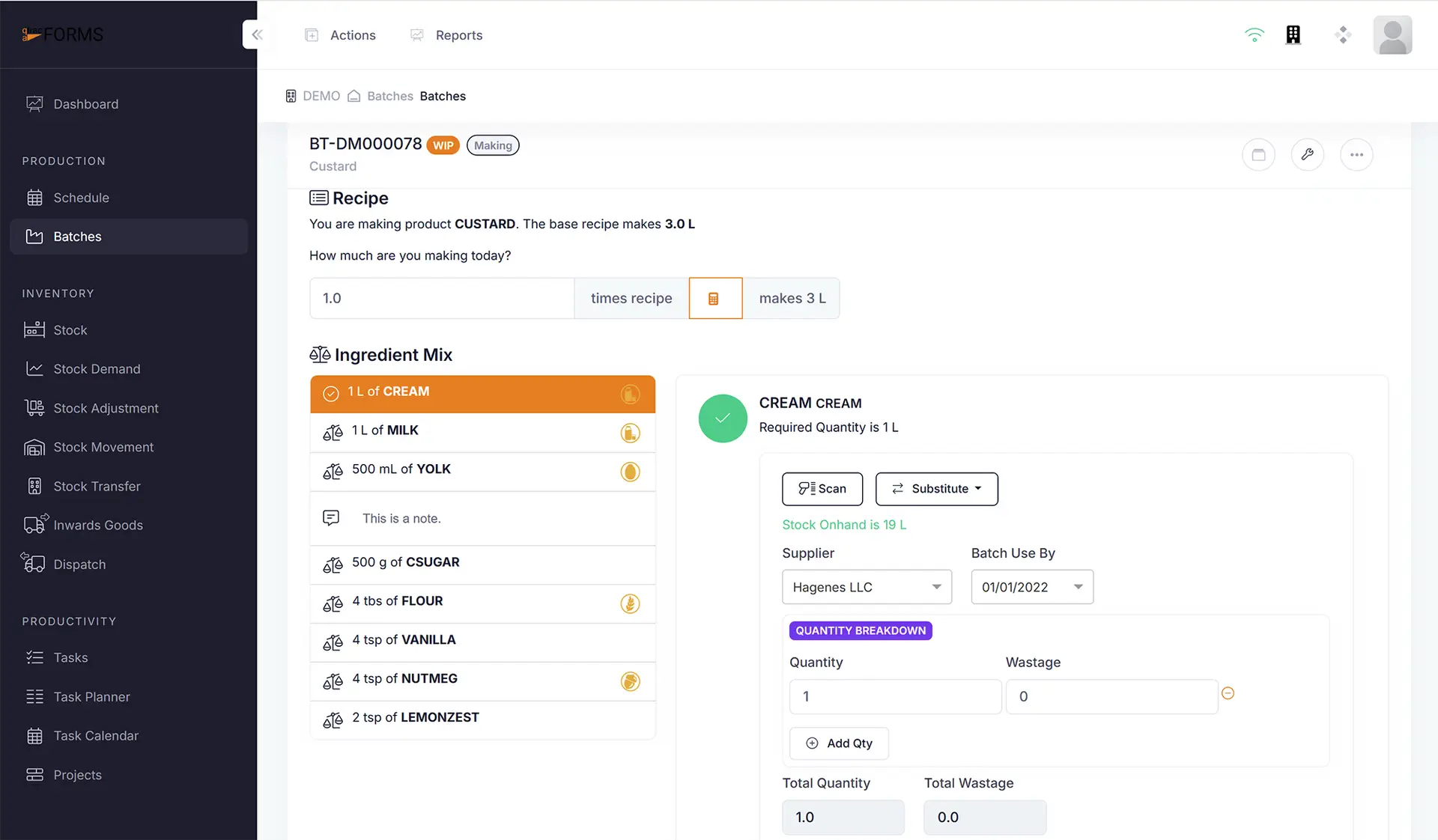

Yes. QTRACA supports unlimited levels of WIP batches in your production process. Create recipes with multiple WIP stages, track which ingredients go into each stage, monitor where each WIP batch is used, and maintain complete genealogy from raw ingredients through all intermediate stages to finished goods. This is essential for complex manufacturing processes.

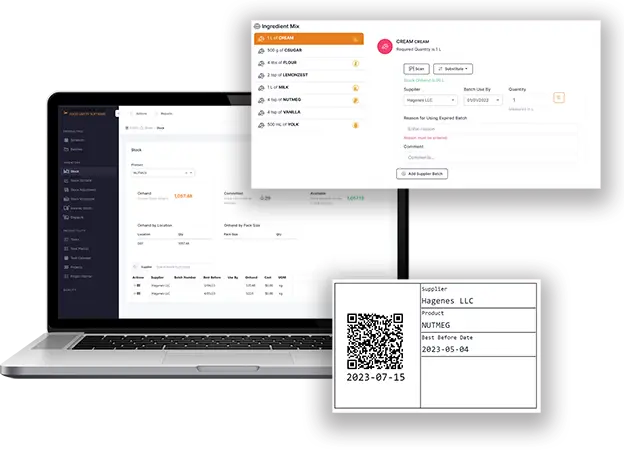

Yes. Generate barcodes automatically when receiving ingredients, print labels for incoming stock, scan barcodes during production to track ingredient usage, and use handheld scanners or mobile devices for inventory transactions. Barcode scanning reduces manual data entry errors and speeds up production workflows.

Absolutely. QTRACA supports unlimited storage locations within your facility or across multiple sites. Track inventory levels separately for each location, record movements between locations, view stock on hand by location, and maintain accurate counts everywhere. This is essential for businesses with multiple warehouses or production facilities.

QTRACA provides comprehensive recipe management. Create recipes with unlimited ingredients and WIP batches, specify quantities and units of measure, define approved substitute ingredients, track costing information, maintain version history showing all recipe changes, and link recipes directly to production batches. Always know which recipe version was used in historical batches.

Yes. QTRACA manages finished goods at the pack size level. Track how many cases, cartons, or individual units you have of each product, dispatch specific pack sizes to customers, maintain accurate inventory counts, and fulfill orders precisely. This is crucial for customer order accuracy.

Yes. QTRACA integrates with Xero, MYOB, QuickBooks, and other accounting systems. When you dispatch finished goods, QTRACA can automatically create sales records in your accounting system, allocate batches on a FIFO (First In, First Out) basis, and keep physical inventory synchronized with financial records. This eliminates double data entry and reconciliation headaches.

QTRACA tracks expiry dates for all ingredients and sends automatic alerts before items expire. Set up custom alert timeframes for different products, receive email notifications when stock is approaching expiry, prioritize using older stock first, and reduce waste from expired inventory. Reports show what’s expiring soon so you can take action.

Yes. Upload supplier certificates (COAs, organic certificates, allergen statements) and link them directly to ingredients or suppliers. Set expiry dates and receive automatic alerts when certificates need renewal. During audits, instantly prove that all ingredients had valid certification. No more lost certificates or expired documentation.

QTRACA makes recalls fast and accurate. Identify the affected ingredient or batch, click to see everywhere it was used, identify which finished goods are affected, see which customers received those products, export the complete list instantly, and have all documentation ready for regulatory authorities within minutes. Fast response prevents larger recalls and demonstrates due diligence.

Book A Demo Now.

See how QTRACA can help you go digital and receive a 15 day no obligation trial.